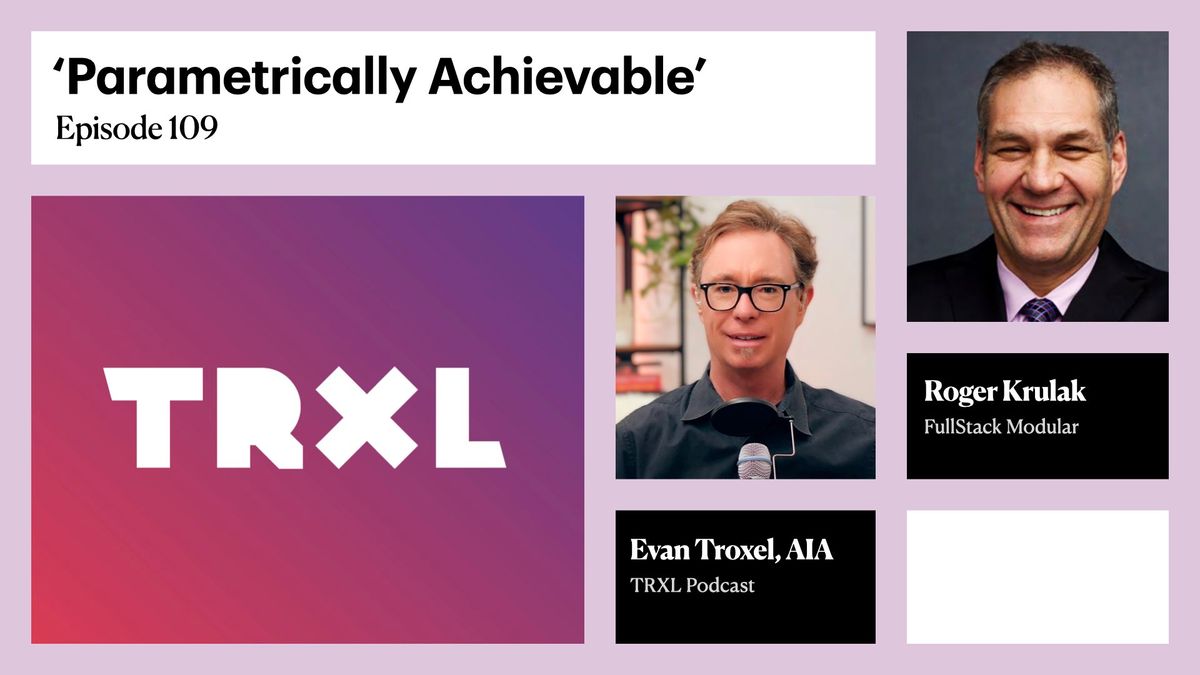

109: ‘Parametrically Achievable’, with Roger Krulak

A conversation with Roger Krulak.

Roger Krulak of FullStack Modular joins the podcast to talk about:

- FullStack Modular's design to manufacturing approach

- how they achieve their deliverables using parametric design tools

- the typical inefficiency of development that drives innovation at FullStack Modular

- the degree to which the building industry is, in Roger’s words, a “big monster”

- Design for Manufacture and Assembly (DfMA)

- the goal of getting the entire team all on the same side of the table

- industrialized construction

- and other topics

Sponsor: TRXL+

- read the announcement

- subscribe to the new TRXL AEC/tech newsletter

- support TRXL directly with membership

- get a special launch discount when you sign up for a year

Latest TRXL AEC/tech Newsletter

Episode Links

- TRXL+ Launch Announcement post

- TRXL+ special launch offer for TRXL podcast listeners

- Roger on LinkedIn

- FullStack Modular website

- FullStack Modular on Twitter

- FullStack Modular on LinkedIn

- FullStack Modular on Instagram

Connect with Evan

Watch this episode on YouTube

Episode Transcript

109: ‘Parametrically Achievable’, with Roger Krulak

Evan: [00:00:00] Welcome to the Troxel podcast. This is Evan Troxel. If I sound a little different. Maybe like I'm coming to you from a different location. That's because I am. Troxel HQ has a new home. I've officially landed in the Pacific Northwest.

More specifically, I'm now officially an Oregonian. So after a short hiatus, I'm thrilled that the podcast is back. If you've been a long time listener, hopefully, you know, by now my goal with this podcast is to add value to the people of the AEC industry.

That's you through these conversations and I couldn't be more excited about the upcoming guests on the show as we track the co-evolution of architecture and technology. If you're new to the podcast. Welcome. I recommend going back to the beginning of the catalog. If you're looking for a master's degree level of education in this realm. Which is all made possible by the incredible guests that have joined the podcast over the past [00:01:00] two years. Before we get into today's conversation. I want to let you know that I've been working on many things behind the scenes.

To get ready for what's next with Troxell and I want to tell you about them now. I've got a new website, which is allowing me to do some great new things. The address is the same@trxl.co.

The first new thing this allows me to do is have a newsletter. I'm now publishing a Troxel AEC tech email newsletter about once a week. And at this point I've already published five of them to help you track the pulse of our industry. So why do a newsletter. it's a way for me to share more granular industry news that adds to the context of the podcast episodes. My goal is for the episodes to be more of a timeless resource. So naturally the topics aren't about the latest news.

And the newsletter helps fill out the spectrum of AEC and tack on Troxell from my perspective. Check it out. I think you'll like it. It's your very own shortcut to the things worth paying attention to, as we track the co-evolution of [00:02:00] architecture and technology.

So far, my readers have told me it's a great format and editorial lens. And one reader said she feels like she should pay me for this. Which is a nice segue to my next topic. So next up is sponsorships Troxell is once again, an independent podcast, I've built a small team to produce the show

and with the changes to the business, I have to find ways to make it work. Ad base sponsorships, which you're already familiar with on the show r something I'm now solely responsible for here.

So if you're a brand or company who has a product or service worth putting in front of this lovely, loyal and dedicated audience of AEC industry professionals, I invite you to get in touch with me by visiting the sponsor page on T R xl.co/sponsor.

But that's only a part of how I'm approaching, making this work. The next thing is what I'm really excited about.

Memberships to what I call Troxell plus. I now have the technology in place to invite you to directly support what I'm doing here by offering memberships. It's [00:03:00] my hope that you see the value of this endeavor and that you will directly support what I'm doing here.

When you become a member, you'll receive some nice perks. And the biggest benefit is that member supported content is ad free. I think this makes the most sense for those willing to directly support what I'm doing here.

So with membership to Troxell plus you'll get your own private feed for ad-free episodes of the podcast and an ad-free version of the newsletter with additional member only content over time. And I'm doing a special launch offer for the next month. That's for you early adopters out there. It's a pretty nice discount that is applied for the first payment for yearly supporters,

A link for the special offer is in the show notes for this episode and on the website. So it shouldn't be too hard to find.

My goal is for the Troxell podcast and newsletter to add value, not only to our industry, but also to you and your career. And I hope in return, you can help me do that and more by becoming a member.

So in summary, we've got a new [00:04:00] season of episodes with an amazing lineup of guests coming. The new Troxell AEC tech newsletter. Subscriptions and memberships with a special launch offer for the next month for you early adopters out there.

And you can see all of this and learn more@thefantasticnewtroxell.co website. That's T R X l.co. There's also an announcement outlining all of the things I just talked about on the new site. And you can find a link to it in the show notes. or@troxell.co.

Okay with that, let's get on with this episode. In this episode, I welcome. Roger Krulak. Roger has over 35 years or bringing innovation to the construction and development sides of the real estate business. In 2016, he founded full-stack modular, which has established itself as a disruptor using advanced technologies for building design and using high rise, modular construction.

Tech-driven and maiden the USA. Full-stack has factories. He's in Brooklyn and Portland, and it specializes in mid and high rise. [00:05:00] Multifamily buildings, hotels, and student housing in urban environments. Roger received the popular mechanics breakthrough award in 2014 for his work on creating a high rise modular process. He also sat on the international panel of experts for Singapore from 2014 to 2016.

He frequently speaks at the country's top design schools and universities, including MIT, Harvard, and Yale. And he's been publicly recognized as a leader in innovation with multiple features in the New York times wall street journal wired, and many others. Roger received his degree in management and organizational psychology from Babson college.

In this episode, we discuss full stacks, designed to manufacturing approach, how they achieve their deliverables using parametric design tools, the typical inefficiency of development that drives innovation at full stack, the degree to which the building industry is in Rogers words, a big monster. Design for manufacturing assembly, or DFMA the goal of getting the entire team all on the same side of the table.[00:06:00] Industrialized construction and other topics. So without further ado, I bring you my conversation with Roger Krulak. Roger, thanks for joining me.

Roger: Evan, thanks for inviting me to visit your show.

Evan: Yeah. I'm looking forward to this conversation. I've had a couple of guests on here before talking about modularized and prefab, things like that, and you're a veteran in this space, and so I'd love it if you could maybe start at the beginning of where did this idea come from? How did you get here?

What is your trajectory been in the industry to get to this?

Roger: Certainly. One way to describe it is that there's really nothing new under the sun. And to be fair, I grew up in a construction and development industry and family. Always we're working on housing projects even from a very young age. And my grandfather was involved in a modular company in the early seventies as part of [00:07:00] Project Breakthrough.

I don't consider myself that inventive. However while I was working for Forest and we had the charge of building 6,500 affordable housing units. I was lucky enough to develop a solution to build high rise, dense urban environment, modular buildings, a significant height, which was in my mind, the breakthrough that has the.

Evan: Okay. That's, that is a lot of housing. 6,500 units. And was that over a long period of time? Was that in a short period of time? Was that one

project like how did

that That's a big

Roger: it didn't actually all get, built, but the reason we created the system was to build it. And then of course one of my favorite quotes, life is what happens when you're making other. The economy was tight. A bunch of the land got sold to a Chinese development company, and so we built the tallest modular building in the world, which is no longer the tallest modular building in the world.

But the system got proven out and, and full Stack Modular has been able to take that and utilize it, across the.

Evan: [00:08:00] That's interesting. So, it's in the name, right? It's this idea of going up with modular, and stacking these blocks on top of each other, like building legos. You said your grandfather had a history in this. It's in your blood, maybe in your dna.

Tell us that story of like, how did you get from not building like this to actually like developing that system to build like this.

Roger: Yeah. I grew up in what you would call the Midwest, which isn't really the Midwest. I grew up in Cleveland, Ohio, and we were very used to building buildings on a very tight margin with very predictable costs. and when I moved to New York not only did my head spin, I couldn't believe the amount that people were working.

But it was incredibly interesting and distressing at how volatile the construction market was for anything, anything of significant size and. For a city of the company that I was working for, had made this commitment to build all these affordable units. And from a business perspective, it just made no sense.

It didn't feel like you could [00:09:00] ever make those kinds of amount of units with that density given the construction environment happen. So, when something isn't working you can either throw up your hands or you can come up with another solution. And I was fortunate enough to be able to be given a little r and d money and create a world-class team to try to come up with a solution to predictably deliver cost effective, mid to high-rise housing in a factory.

And that's where full stack modular. Really started.

Evan: That's interesting. So just the ability to make the decision to try something completely different. did that get birthed inside of four cities Yes.

that's a huge risk.

Roger: it was a huge risk. And I remember even today, the investment committee conversations about should we try this to the credit of the, former executives of foresee they decided that it was worth it.

And I believe that it [00:10:00] was the next big step for the modular and certainly fully volumetric modular industry to allow it to move forward where you see the kind of growth that you're seeing quarterly

Evan: I just, I wanna pause on that for a moment because I think that's kind of rare, and at least in the architecture space for a company to. Take time out to explore a completely different business model. And I can only imagine, it's not only risk from the standpoint of you're doing it differently, delivering in a much different way, but all of the infrastructure it takes to put in place to actually make that happen.

To build the machine, basically to produce and take total control over that entire aspect. Because when you're going into this paradigm shift compared to the type of way you're used to delivering buildings, you're now responsible for every single piece of it, and I guess as a developer you kind of are, but it doesn't mean you do it all, right?

You maybe [00:11:00] orchestrate and do those things in the background, kind of like an architect would do with a building, right? They draw the plans and then they observe or they do construction administration. They're not actually doing that kind of stuff, and so to. Do this kind of business model shift and actually take charge of all of that had to be like, I'm just wondering like what were those kinds of conversations like for the business to say we're willing to explore that

Roger: Well, first of all, great question and I think you far underestimate the amount of effort that

takes because it's not only, it's not only, yes, we're taking all of this under our own wing. It's we are gonna change the trajectory of design bid, build process that is 13.5% of the world economy.

And we're gonna tell everyone that they should follow a design build approach or a design manufacturer approach, because that's the only way you could really build modular buildings. That's on one side and on [00:12:00] the other side. Anybody who's been in the architecture or engineering industry for a long time knows.

Over the past several decades, if not several score the movement away from collaborating on decisions in a way that is effective and coming up with complete executable designs has been going the opposite direction. Partially cuz of the insurance industry, partially because of the insurance for the professionals involved and.

not only do you have this sort of iterative value engineering process, you also have hands off approach, by force for two reasons. One of 'em is the developer doesn't want to pay the upfront costs that it really takes to do a comprehensive design engineered and two is that the insurance companies don't want the architects to.

The mechanical engineer, that, that system's not gonna fit. So in some ways I agree with you. It is a lot to take [00:13:00] on. On the other hand, I didn't really see the way that the industry who was moving, that there was any other way to get anything done. Before I had to retire.

Evan: Yeah. So, you had to do this , that's

Roger: I do feel like maybe, I don't know if I had to do it, although I am, I'm definitely someone who likes to shake things up if they're not working. But I do think the industry needs this as a tool. The shift in the industry must be design build for anything that.

Pally achievable. And multi-family buildings have so many fixed parameters. You're not asking for a lot. Whereas you know, museums or bases or, new city developments, there's not that many parameters. You have a lot of flexibility.

But if you're building a mid, the highrise. You need elevators and hallways and stairwells and windows in the bedrooms for the most part. And, [00:14:00] like you, you don't have that many decisions to make. We had a few and it ends up being a little bit more controlled process, but at the end of the day,

The one thing we do is we design for manufacturer. We make it that you can build it in a factory and stack it up like Legos, as you described. And the only way that happens is if everything is built to the exact precision that it needs to be in order to be able to put it together.

Evan: Yeah. I can only imagine the huge shift that had to happen as you went through this process for the development company, not only from what you're delivering, but also how you're delivering it. How the team produced the things the learning that had to happen to produce for manufacturing.

To draw for that or to model for that. And so maybe take us. Through some of that process that happened because this is a major evolution for a business to go through. And I think on many levels people think they have to start over or start fresh rather than [00:15:00] try to change the thing that already exists into something else.

Roger: So actually I think it is an interesting question, and I'm not sure if I'm going to answer it directly because I look at it this way. I look at it as the inefficiency of development from the world we play in, which is, housing of any sort, hotels, student housing, affordable housing.

Market rate, the deficit in all of those markets is relatively insurmountable, and the production of housing units worldwide and the United States pick a state is well below the need. So, it's really hard to imagine that we as human beings and innovative people and, in a very wealthy part of the world, can't solve a problem.

And we have created, I hate to say it, a big monster. I mean, The industry is slow and inefficient across the [00:16:00]board. And so that frustrates me to no. and uh, one option is to quit and become a cook, and the other is to try to shift the way that we do things. And yes it is a colossal effort.

It requires exactly the opposite of the process that as an industry are used to. And it also requires a shift in attitude for all of the players. I mean A design build team is all of the stakeholders sitting on the same side of the table trying to figure out how to accomplish goals.

That is not how we as an industry have been behaving for, I don't know whether it's 50 years or a hundred years or 400 years, but it's for a long time

Evan: And, how long has Four Point been in business previous to this

Roger: Forest City. BU business for a hundred years. It's a hundred plus years. Yeah. I it. And to be fair to them, the modular business that I mentioned was actually originally part of Forest City in [00:17:00] the seventies. And It failed because they had one customer which was the US government and once that project breakthrough, which was affordable assisted living facilities once that program dried up after the end of the Carter administration that business dried up. And and that was showing my age a little bit, but I was a young kid when that happened. . So, I remember it very distinctly and it was a concrete solution and it was amazingly efficient for what it was, but amazingly inefficient for what it is that we're talking about right now.

Yeah. So take us through

Evan: kind of

Roger: how tech plays into this, because I think you said that started around the 2008. Recession time.

And obviously there's been a huge shift in the last, 15 years over in the technology space and things are moving quickly.

But give us an idea of how that started and how it's going now, because I can imagine there's been huge developments in that.[00:18:00]

Oh yeah, it's interesting because mentioned that this early 19 seven. Modular was literally people drawing on, blue line paper, trying to create a way to manufacture things in an intelligent way when you really couldn't , there was no parametric design.

There was no CAD really to speak of. So in 2008 it was way farther along than that, but it was still pretty early on in the evolution. Of, AI tools, parametric, generative tools and all of the things that are now rolling out on a daily basis. but the three dimensional, cad drafting, whether that be in a Cilla framework or a Revit framework.

It existed in 2008 and has always been necessary because unlike a building where you have specifications that say, mechanical ducting has to be at this tolerance and steel has to be at this tolerance, and wood has to be at this tolerance and plumbing pipes have to be at this tolerance.

If you [00:19:00] think about building in pieces, everything has to meet the same tolerance. . , so drawings had to be preci. A and the integration and clash detection and all of the things that we talk about are matter of course, for building. Offsite and having the tools to measure that accurately, which was a huge challenge in 2008.

And basically you can buy on Amazon something that measures to that accuracy if you know how to use it today. So, it's a big, it's, so technology is making this process significantly easier and um, the risk factors significantly. As long as you're considering the right parameters.

Evan: I want to go back to something you mentioned a minute ago. The inefficiencies of traditional construction that you've lived through and grown up with versus what you're experiencing now with this that you can't achieve without technology and without all the players at the table, [00:20:00] without them all sitting on the same side of the table.

If you were to throw a number out, what would you say is the waste in that process? If you were to think about it from like a, dollar signs, right? If, is it 50 cents on the dollar versus something way less in this, Direct to manufacturer type, like what? There is so much at so many levels.

If you were to just kind of take a swing at that what do you think that number is? That everybody who's dealing in the old paradigm still at some level is just accepted. They've just accepted it.

Roger: that's such an interesting question. And one day maybe I'll have the money to pay somebody to figure it out, but I think these are the things you have to think about what they cost, for instance, , how much does time cost? It obviously costs a lot more now than it did seven months ago. How much does when we were at Forest City, we did a lot of residential hunting.

Like how much does a development process where you're kicking the tires and all of the people you're [00:21:00]paying to do that and the architects and the engineers and the lawyers for projects that never happen how often does that happen? How often does somebody have a development idea and then they go send it out to a general contractor, the price comes out, double what they can actually afford to make the proforma work in.

And then how much does it cost when you buy out a project, you sign a. Where you're not on the same side of the table and the general contractor or the architect used the holes in the project to get change orders and increase costs. So what do really contracted projects, how much do they really cost at the end of the day?

How late are they? How much does that cost? So, you're asking a question that I'm trying to put all the pieces together and my guess is you're probably if you were able to calculate it in the 30, fully in the 30% range of wasted money now, of course it diminishes if you're, doing multiple [00:22:00] projects in both cases, if you're doing multiple projects that are somewhat similar and obviously geography by geography the dollar shift.

But I would not be surprised if that's not a 30% waste number

Evan: I wouldn't be surprised if it was higher than that. I've heard it as high as 50 cents on the dollar. And like, that's a big dirty secret to people who buy buildings, owners who do the development. And

it's because an enormous amount of waste in the process , and that speaks to these types of solutions that you're talking about,

with owning this whole stack all the way through and the amount of efficiency that you can gain by doing it. And you said it's not for everything, right? It's not the solution for all buildings everywhere, but it is, it does fit quite a few different verticals. And it seems like, I'm just wondering , did you guys think about that when you were first starting out with this idea about that the sheer amount of waste that could be avoided or at least that you could get a lot better at over time?

Roger: Yes. The interesting thing about it is that, a, [00:23:00] a factory or a productization, regardless of what it is, whether it be housing or cars or telephones or, earth movers the value proposition is the more that you manufacture something, the more you get efficient in it.

If you think about The actual construction, the hard costs as it were. You have labor and materials. Can you actually buy materials better if you're manufacturing them? Maybe a little bit. But what the real opportunity is labor savings, right? And labor savings happen on on logical repetition to meet the market deed of what's going on.

And so, The value proposition is so antithetical to the way that we do development today that requires a mind shift. And there are people that are getting it now, but when we started in 2008, every meeting I went into, somebody under their breath was talking about how out of my mind I was

Evan: I can only imagine you, this'll never work kind of talk.

Roger: Oh, [00:24:00] you have No, I mean I have so many stories about people who were actually even in the modular business telling me how it was crazy and maybe I am , but it's so nice to see the industry growing at the rate it is. And I just heard that like the world of modular is expecting 1200 people this year, people from 20 countries. A part of the industry that is not stopping right now. And I think that the level of improvement in innovation that's coming our way in short stead is exciting and worth noting. And the good news is that, I don't know a developer who has any major pipeline that isn't asking someone in.

either in their world or in their company to invest in understanding the opportunity.

Evan: Yeah. Yeah, I can imagine. They not just through a diversification like program, right? Like they, I'm sure that they want to and like you said, the more you do it, the better you get at it. The more comfortable you get, the less risk there [00:25:00] is because, , you're building tools, you're building knowledge, you're building all these things along the way that only help over time.

So yeah, I can imagine that's only gonna be continuing to grow.

Roger: Yeah, I mean, talking about technology, imagine you get a floor plate that works modularly, that's a series of three mods that, varies, whether it's one twos or threes. You get that all laid out and then you write a dynamo script to create the rest of the building. Pretty darn efficient,

so.

Evan: Let's talk about that tech stack that you guys have developed. You're talking about something that's now you said, been in development since 2008. I'm sure a lot's changed, but give us an idea of the kind of the tech stack that exists.

And I don't just mean software. I guess I'm interested in all of it, I'm interested in as much as you're willing to share, like what is the process, what are the tools, what are the things that. let's even narrow it down a little bit. What's possible now that wasn't possible five years ago?

And how do you at [00:26:00] Full Stack achieve?

Roger: Yeah, I think. , it's amazing cuz I talk about, how exciting that technology blend with, design and manufacturing is. But the interesting and most important thing is what I've been talking about a lot, which is the thought leadership, and. Parametric process by which we create buildings, as a group of developers, engineers, architects, contractors and the collaboration tools associated with that also require the willingness on the part of the participants.

So, for instance, and I'm not ignoring your question, I'm just sort of

up, One of the things that has to happen in the design for manufacturer process so that you can utilize the tools, some of which I already mentioned, is that you need an architect and engineers for that matter, to be willing to share agency with the system that we're going to use [00:27:00] to create the building.

So full stack modular. A system, it has a structural system, it has an m e P distribution system, it has a waterproofing system, it has a self-sealing facade system and it has an erection system and process. And all of those are part of what we have. So now all of those pieces and parts have both physicality and technology associated with it.

Now what we need to do is we need to. An architect, we need to share those pieces. As sort of a portion of the agency , tools with which the architect can use to create the building. So that transfer is two-dimensional information, but it's also three-dimensional distribution and.

Understanding of how the things go together on the site. And all of those things are part, not only of our system, but also part of our [00:28:00] process. So, it is not anymore. Getting a completely designed building that doesn't pencil out conventionally saying, can you modularize this and make it cheaper?

Please wave your magic wand. The people in the industry are understanding that it is something you have to be willing to share if the architect or designer or developer is willing to incorporate these systems and processes into the design for manufacturer process, it goes a lot faster

and cost predictably so.

Evan: I'd like to get back to the tech and the tooling part of it. Cause I think the audience would be interested in hearing what those pieces are robotics involved, obviously CNCS involved and it goes, I'm sure way beyond that.

But the idea of, I've done some of the panelized construction, not modular, not volumetric, modular. And one of the things that was very clear was that it wasn't cheaper, but it was faster

when,

and that only became clear to [00:29:00] us over time. That wasn't even said upfront. I Obviously speed is an issue.

In construction projects. The projects that I was working on happened to be education facilities, which have, a deadline. Is about kids getting into a classroom at a certain date. And so working from there backwards it kind of boxed us into using a system like this because the speed was so much greater, but it didn't cost any less.

Is that still true? Is that because, I think, can you modularize this and make it cheaper? Is kind of an uneducated question to ask because it's like there's three constraints. Pick two, right? It's fast cheap is that still holding true with the solutions that you're offering from Full Stack

Roger: I think I mentioned a little bit earlier is like, what does a building cost just because bought it at a hundred dollars , did it really cost a hundred dollars? At the end of the day, chances are no, but on top of. I did explain that the repetitiveness and utilization of the system and the ability of the labor, whether [00:30:00] that be robotic labor or human labor or some combination the repetitiveness of it increases speed, decreases cost.

So the more that gets embraced, the more chance you have of decreasing the actual cost, you're definitely gonna also decrease the time. And they're linked to each other. So, with a repetitive process, you definitely have the opportunity to save, I would say, up to 20, somewhere between 15 and 20% against a conventional solution of the same type.

So that is definitely possible. but and it requires incorporation of those system and processes in a way that is incorporating, diminishing the amount of variability, circulating around a corridor with units rather than mirroring them using a minimum amount.

Variety of say, modules, maximum of six instead of 27. Because all of those things increase productivity and the capacity to [00:31:00] automate it in a rapid shifting form. So

whether that's machine

code or instructions for a carpenter to build or anything.

Evan: So if we get back to the idea of like, what in your world is now possible that wasn't possible five years ago and learning everything that you've learned, is there anything you can share in there that is an interesting process or tooling or system that is really changing the game for you guys in the last five?

Roger: Yeah, I I think one of the things that I mentioned earlier, which is that if you can come up. Floor, even a two dimensional floor layout that works using our parameters. You can write a dynamo script to do all the drawings. I mean, In a modular building, the production drawings are, for a hundred thousand foot building thousands and thousands of pages.

It can actually be created in a couple of hours by running some scripts that really didn't exist in 2002 seven 2008. The other thing, obviously that's happened because, The evolution of the [00:32:00] industry as a whole is we didn't really have access to libraries that had accurate dimensions in them in 2007, 2008.

Occasionally you would find one, but there is nobody in the industry right now that doesn't have I shouldn't say there's nobody, there's almost nobody I found that doesn't have an. CAD library that you can access to make sure you use those pieces correctly. And they're dimensionally accurate.

And for us with precision of, less than an eighth of an inch across all systems, that's a huge deal. So that's a big advantage. And of course, the transferability because, so, Companies, AutoCAD, Katia, they've all been focused on integration for manufacturing.

The cross code cross data, common access to information is so much more available than it was so much in 2007. 2008 was hard coded , so every time you change something, it didn't [00:33:00] work. And so much of that exists today is relying on, transportable data sets.

And so that's a big advantage.

Evan: Yeah, I can imagine. Can you give us an idea about the full stack modular itself? The company, like how, what kinds of divisions is a weird word to use in a company where you're talking about full integration. But how is your company set up to operate in this really collaborative way where everybody is

Roger: Yeah.

Evan: of the table?

Roger: We are definitively always design manufacturer solution in what we call the sort of design manufacturer construct world, which is design, build, insert industrialized cons. . So we are always that and we are often collaboratively working with a general contractor to provide a full design manufacturer construct turnkey solution.

But there is really no way in our world to do our job unless we are not sitting at the table day one with the design [00:34:00] manufacturer construct team and driving. , everything that goes through the point that the mods are wrapped and ready to go to site. That's what full stack.

Evan: Okay. I remembered what I was gonna ask you earlier, and it has to do with that last piece that you just mentioned about getting it to the site. And I've heard from other, either modularized construction, actually I heard it directly from a volumetric modular guy, was it starts with logistics.

The design problems, like, can we get the things to the site on the site, placed on the site? And if we can't, basically you start there and work backwards because if you can't, it's not a, it's not an option. So is that still hold true?

Roger: It's funny it's, people say that to me all the time, and I'm not saying there's not a place where you can't put a big mod because of course there is. But I'm, like I've been in New York for most of my career, so I can pretty much get a mod anywhere, I actually would say and by the way, I'm not dismissing that.

Obviously moving something that's [00:35:00] 12 to 14 feet wide and 30 to 40 feet long, that weighs, 15 to 17 tons is nothing. It's not, it's something you have to think about. But to me, the biggest concern, and we talked about it earlier, is.

What gives value to the end user, whether that be the developer themselves or the people who are gonna live in it, what gives value to them and how do you make sure that you're preserving some of that value for them? And one of the big frontiers in industrialized construction right now is how do you make sure that the work that's going on.

Doesn't absorb all of the savings that, industrialized construction creates. And that interface is key. And we have full stack been spending a lot of time on that. At this point, collaboratively, we're not doing it ourselves, but we are spending a significant amount of time creating technologies, whether they be augmented reality or, [00:36:00] effective.

Graphic 3D communication on how things go together on site so that they can get the people that need to put it together, the right information so they're not overcharging for the work that happens there. That's a big frontier in our industry right now.

Evan: Yeah, so the idea of 4D sequencing ahead of time, that's a big piece of the puzzle, right? Because basically then you're providing the instructions to the installer to do it. Like you've thought through all of those logistics up front.

Roger: Yeah. Not only have we done that, but we've done I currently have an onsite electrical design for small, medium, and large building. I can quantify how many connection points that are gonna happen so that they can look at the trades that will need to make those connections. They're gonna get all the pieces and parts that we manufacture in the factory in order to connect them.

Because we are an all modular solution. The full SM e p is done in the factory and [00:37:00] just needs to be connected and we can show them drawing. And 4d, sequences of how that happens. We're not sending them out with, glasses right now, but we can certainly provide them, you know, an iPad that shows, oh yeah, this is how you do this connection.

Now, if you can take all that and say, okay, Mr. Onsite plumber, you're doing 168 of connections that look exactly like this, it's much easier, and we're taking all the risk out of it. If we make, at full. If we make a mistake based on the design and dimensionality, we take responsibility for it.

But assuming you're getting everything you need, what do you need to do? To me, that's the place where there's opportunity and savings to be aggregated for the end user. Whether that be an owner or developer.

Evan: Yeah. It's so interesting to see this shift over. Decades, I guess of, remember when a set of plans was 12 sheets? And the contractor was responsible for figuring out [00:38:00] how to run the ducks. And like we had a lot of single line diagrams back then, right? For H V C, for electrical, for plumbing, all those things.

And now, That is flipped, right? The script is flipped there, and all of that's figured out upfront, which makes the modeling process a lot more complicated, complex, right? There's a lot of complexity there. How do you feel about all that? I mean, Obviously there's huge efficiencies to begin there, to spend the time up upfront and not worry about that stuff. Not working when it's time for construction. So I'm sure you feel positively about it, but it's also a huge shift in the industry to put all of that onus on the designers up front.

Roger: Yep, it is. But look, it wasn't always that way. If you step back 20 years before when you're talking, like it was all like that. Everything was completely designed. It wasn't necessarily in 3D CAD because there wasn't 3D cad.

Everything was absolute at that time. The engineer knew exactly what they wanted and they there had to be some [00:39:00] coordination from class detection because there wasn't a way to, accurately. But those, if you look back, through the archives 50 years ago, the drawings were a thousand pages then, so I think actually we're just getting back to basics in my mind, and I think relying. , some random person who's the lowest bidder on a project. To be able to figure out what it is that the engineer had intended is a little bit delusional.

Evan: what could go wrong? Yeah,

Roger: Exactly. Exactly. Well, look, you're talking to the wrong guy to give you an opinion on that because I don't think there's really any other smart way to do it.

Evan: Yeah. Interesting. So, okay, so what are you excited about in the developments? What's coming out? Like you're making a case for this. Type of methodology of procurement for buildings for, obviously there's a huge demand and need for housing, like what you're specializing in.

And this is a great way to deliver and it doesn't all have to be capital [00:40:00] a architecture. Not that what you're doing isn't, but there's a huge need out there. We only need to do more of. Make the case for why people should be at least, architects and engineers who are interested in solving some of these huge problems in our society that need to be addressed for the way that you're going about it.

Roger: Yeah, I think. We all in this industry wanna see the things that we create

Manifested, and we talked about how many of them don't get

Evan: Yeah. there's there's a great saying, If it doesn't get built, it doesn't count that, that's in a

Roger: Yeah. so I'm like and I obviously lots of friends who are architects and engineers, like who wa you know, all the projects that never got built, who cares? And so, I never would say that, volumetric, modular construction is the answer to everything.

But in the world that we play in, it's radically. And so, if you wanna see things get built and you don't wanna spend your [00:41:00] life in job meetings talking about like, which toilet you're using, even though the project hasn't even been financed, like this is a really good way to do it, is it gives you an enough added parameters to.

It. And I love architecture, but to give architecture the ability to change the way that the building feels in the environment in which it's going to live, and the way that the people who live in it interact with the space that is created for them in a highly sustainable, incredibly carbon responsive way.

That doesn't require you to reinvent the wheel. And so if you're an architect who's in the multi-family hotel, student housing space, like this is a tool that you ought to at least understand the value proposition, and I think you're gonna like it.

Evan: Yeah I, you check a lot of boxes [00:42:00] with that, with your sales pitch right there, because can only imagine too, and maybe you can shed a little light on this but this is a scale question, but it's like, h how many projects are you guys doing a year? It seems to me with this approach there's more throughput as well,

so you're realizing more designs getting built than a typical, outfit would.

Roger: Yeah. No, I think the percentage of throughput is bigger. I think the other thing that is worth noting and something that you just touched on is that. , when you're manufacturing the throughput isn't necessarily what comes out of your specific geographic location where you're assembling mods, but it's what can you get through the process in a way that is.

That is time effective quality, effective, and produces what it needs to. Manufacturing has always been a maker buy conversation about everything that you [00:43:00] do. Construction hasn't generally been that way because the decision making was so dispersed between, the trade jurisdictions and the engineering jurisdictions and all of those things.

The one advantage that you have when you're manufacturing is you are just trying to figure out how to optimize what it is that you're creating and meet all the required parameters, including design, , including code, including, technology integration, including sustainability, including all of those things.

But you have lots of flexibility in how you do it, and frankly, it doesn't really matter. Unless there's some regulation associated with it, where in the world , that piece and part is created because you're putting it together in a manufacturing process rather than in a construction part.

Evan: That just reminds me of the Toyota production system,? , car makers in the us. Is kind of the Toyota idea back in, the seventies was just in time manufacturing versus warehouses full of parts. I'm sure you're familiar [00:44:00] with all that.

So can you go into that just a little bit to talk about that? Because, like you're saying , if parts can come from anywhere, , obviously this is still a logistics issue, like a procurement issue of all those things because you need 'em all to put 'em all together and it has to go in at just the right time so that the thing can ship out and get put onto the site in a complete manner rather than, like there were stories of, the Ford production line where, because nobody was allowed to stop it, pieces got left out, for instance.

So, how is that working with your guys? Are you guys buying all that in huge bulk numbers, or are you buying just what you need, just when you need it and dealing with it from a, as you go standpoint. How do you view that

for your strategy?

Roger: every time, all day, our purchasing department is a maker buy conversation, so, every time we're building a project, it's should we be making this in the factory? Do we have capacity and labor or should we be buying it so that we could get more throughput so that we could [00:45:00] meet our schedule for the next three buildings coming out?

And then the good news is that a lot of the suppliers who traditionally had been very construction focused either you get a hundred percent of everything or you get what we have in stock are now very open to packaging, assembling, delivering, kits of whatever we need whenever we need it, which makes that a lot easier.

And oftentimes they'll warehouse it for.

Evan: That's interesting. So what have we not talked about, that we need to talk about here? Is there anything that we've missed that you think is worth putting out there into the audience's ears?

Roger: ,

Yeah, it's reiterative rather than necessarily we've. But this process does require a significant shift in approach and attitude by all of the parties. The value proposition is significant, but the request is also significant if you [00:46:00]don't change the way that you develop projects collectively as a team, not only.

This process, this design, manufacture, construct, process, network. But in my mind, we have no hope of ever meeting the current need which is only growing.

Evan: Right.

Roger: And I want everybody to absorb that because we have a problem and we're not solving it.

Evan: Yeah, that's a great call to action and obviously you're a great example of making that decision and pursuing it to the nth degree. You have any words of advice for people taking that first step. What would that be? Because is it to talk to somebody like you? Is it to go to the conference that you talked about earlier on , like, where do people begin this process? Because if it truly is about meeting the needs that are out there, then .

These companies like Full Stack Modular, need to be willing to share. I assume that's [00:47:00] happening in certain capacities. So where does somebody.

Roger: I would pick a project that you want to develop and commit to following this process, at least from an initial. Engineered schematic design to see how it works. If you have the opportunity and your friend is doing it, then , by all means, sit in on their process.

But I would give it a shot because the chances of you being severely disappointed are slim. The possibility of you not recognizing all the savings that you had hoped. Significant, depending on how seasoned the team is. But I do suggest that you, visit some projects.

There are projects all over the world right now that are fun to look at. Some of 'em are the tallest modular buildings in the world. Some are the largest installations. Some of them are super automated factories. There's a lot going on and. . And so I would dig in and and take a little bit of a risk because there are [00:48:00] many competent, industrialized construction opportunities in the United States and in the world today, and it's growing daily,

Evan: One last question here, because this has crossed my mind a few times now is how regional are you?

Roger: We have a factory in Portland, Oregon, and we have a factory in New York. And generally it's around 500 miles, but we. Building some stuff for export right now? Both to the Caribbean and out even farther. And some of our projects in Portland, because we're right on the water, are significantly longer, 900 miles or stuff.

So from San Diego to Seattle. So there are opportunities, we can't really do anything anywhere. There are, transportation limitations from a cost perspective. So,

500 miles is, thousand max, I think much more than that in you're significantly decreasing the value proposition by the cost of transp.

Evan: mean, I bring that up because, you talk about going [00:49:00] into this type of delivery and procedure workflow, like there's room for more, right? There are a few companies out there like yours who have been in this for a long time and who have a. Experience and knowledge and wisdom about it, which is super important.

But at the same time, there is room for a lot more players in this market because the geography like, like you're talking about, the logistics, the shipping, like all of those things. We need this kind of thing all over the place to be able to meet the demand that exists.

Roger: Yeah. That is our view. And if you fast forward five years from now, our goal from full stack modular's perspective is to. , a front end franchisable solution so that people can run their own factories wherever they want in the world or in the United

States,, et cetera.

That's where we'd like to head because of what you just said, the, it's generally relatively local and the [00:50:00] needs all over the world are significant.

Evan: Mm. . Well, Roger, this has been a fantastic conversation. There's so, so many things packed into this episode that I'm gonna do my best to pull out the salient bits and put 'em into the show notes. And of course we'll link to Full Stack Modular and you online. Is there anything else that you would ask of the audience or that you would wanna point them to, to finish up?

Roger: I would encourage you to watch what's going on in the industry. Put ticklers for, Podcasts and presentations and news that's coming out, which is literally on an hourly basis on things going on in industrialized construction and modular industry.

Because it's both fast moving and significantly improving as we speak and live on a daily.

Evan: Fantastic. Well, Roger, once again, thank you for this conversation and I'll include all of the links to the appropriate things in the show notes for this episode [00:51:00] where you can also follow along with what Roger is doing. So Roger.

Roger: Thank you, Evan. Appreciate it.